Les produits verriers

SAPPHIRE GLASS

Sapphire or crystalline corundum is artificially manufactured, unlike its precious gemstone namesake.

Sapphire is generally produced by crystallising aluminium oxide powder (Al2O3) at a very high temperature and pressure.

However, there are various sapphire crystal development processes, and the most widely used are ISM (polycrystalline), KY, HEM, EFG and CZ (monocrystalline).

Advantages :

• Very good transmission in the UV range – close to IR.

• Incredibly resistant compared to other optical glasses (thermal, chemical, mechanical shocks).

• Very resistant to scratches and abrasion (9 on the Mohs hardness scale, just below diamond).

• Very high melting temperature.

Applications :

• Photoelectric sensor.

• Watchmaking: watch glass (can only be scratched by diamond).

• Scanner glass: often subject to scratches.

• Telephone screens: used for digital fingerprint readers, smartphones, cameras and some watches.

• Windows that must resist extreme temperatures or pressure: laser applications.

Disadvantages :

Its extreme hardness makes it a difficult material to machine, which therefore limits the complexity of shapes possible.

Download technical document : FICHE_VERRE_SAPHIR.pdf

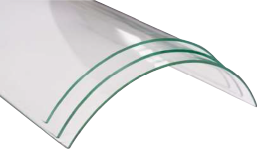

CURVED GLASS

• Fusing or thermoforming: using glass that will be heated progressively in a kiln. Once the softening temperature is reached, the glass fits over or into the shape of a convex or concave mould by the force of gravity. • Cutting of tubes or spheres: depending on the dimensions requested by the customer, we can cut sections of tube ranging from 9 mm to 465 mm in diameter and spheres from 85 mm to 420 mm in diameter. • Moulding (or press moulding): process used for more complex shapes that cannot be obtained through thermorforming, or for very thick parts. • Machining.

Applications :• Cameras, lenses. • Protective screens (dome for cameras, store windows, light fixtures, etc.). • Watchmaking. • Aquariums.

Advantages of curved glass: Depending on the application(s), dimensions and finishes, there are several manufacturing possibilities. Disadvantages of curved glass: The tools required for manufacturing (templates, moulds, etc.). Types of glass that can be curved: Borosilicate glass, soda-lime glass, quartz, optical glass. Download technical document : FICHE_VERRE_BOMBÉ.pdfLAMINATED GLASS

Laminated glass is made of 2 or more single glass sheets (annealed or tempered).

These sheets are glued together using one or more PVB films (polyvinyl butyral).

In the event of impact, laminated glass provides a protective barrier.

Applications :

• Floor panels, stairs, guardrails

• Automotive

• Protection of buildings: anti-intrusion, bulletproof, explosion proof

• Doors to industrial machines

• Protection of display and advertising screens

• Protection of artwork

• Fire resistant or flame resistant panels

Advantages of laminated glass:

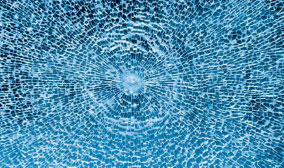

• If broken, it absorbs a certain amount of the impact energy. The PVB film prevents shards from coming loose, therefore ensuring residual protection before the damaged piece can be replaced.

• It also improves acoustics by attenuating certain frequencies. It can be transparent, coloured or ground.

• It provides a very good level of protection against UV rays.

Disadvantages of laminated glass:

• Difficult to cut and drill

We provide tempered glass in the form of:

• Discs and sheets.

Download technical document : FICHE_VERRE_FEUILLETÉ.pdf

TEMPERED GLASS

• Windows for rolling stock • Protective glass for industrial machines, anti-intrusion, building façades, furniture • Lights, explosion-proof boxes, portholes • Laminated glass that has also undergone tempering can be used for applications that require compliance with specific safety standards

Advantages of tempered glass:• Relatively low cost, easy to use, possibilities for sandblasting and screenprinting.

Disadvantages of tempered glass: Once tempered, it is no longer possible to work the glass (no drilling or cutting). Technical data: On average, the theoretical values for mechanical properties of tempered glass are 3 to 5 times higher than those of glass that has not been tempered. We provide tempered glass in the form of:• Sheets, discs, curved glass (before tempering), laminated or multilayer laminated, double glazing.

Download technical document : FICHE_VERRE_TREMPÉ.pdf