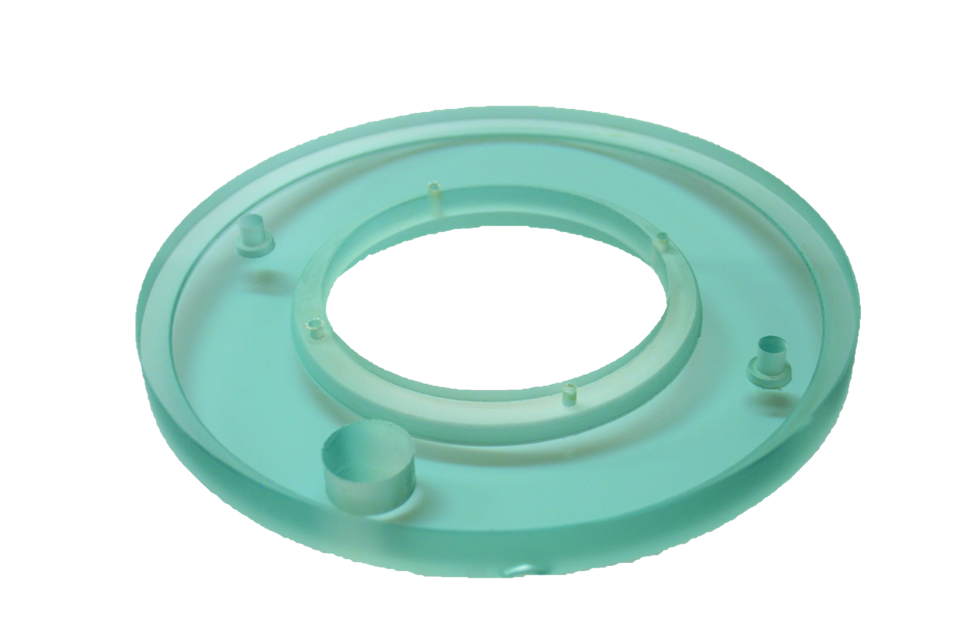

Étape 1 : design

• Supply of plans, drawings or 3D renderings

• Explanation of the product’s end use

• Definition of requirements: mechanical strength, thermal resistance, transmission specifications, dimensional requirements, quality requirements, etc.

• Project timeline (short, medium or long-term)

• Target price

Étape 2 : material definition

• Selection of the type of glass: Borosilicate glass, soda-lime glass, quartz, glass-ceramic, optical glass, etc.

• Selection of any treatments to be applied to the design prototype glass (anti-reflection, anti-scratch, UV protection, etc.)

Étape 3 : production launch

• Selection of a manufacturing technique (manual, semi-automated, automated)

• Hot work (blowing, lathe work, glass/metal fusing, flame polishing, etc.)

• Cold work (cutting, marking, gluing, etc.)

• Pricing of the tools and design work = > a first quote with a delivery schedule is issued

• Modification of parameters, if needed

• Validation

• Creation of one or more prototypes

• Modification of parameters, if needed

• Launch in small, medium or large series

• Quality and conformity control

Organisation of the various process steps, reporting and collaboration

Our team will advise you on which glass is best-suited for your needs, in line with your requirements.

Through our partnerships with accredited laboratories, Verresatine can also provide:

pressure resistance certificates, temperature resistance certificates, dimensional surveys, etc.